Compact Apollo Two-Ram recycling Balers

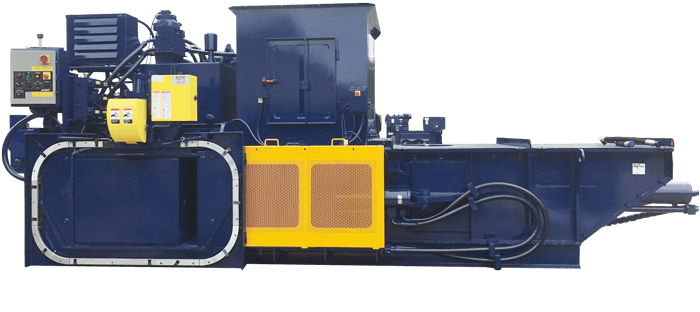

Marathon® Apollo two-ram recycling balers are designed for smaller applications that our other Galaxy® 2R Narrow and Galaxy 2R Wide recycling balers may not be able to fit. The Apollo recycling baler features a full-penetration compaction ram to produce high-density bales. The programmable PLC controller comes standard and features automatic and manual controls, diagnostics, and bale set-up functions. This controller also allows for easy switching between different recyclable materials.

The Apollo two-ram wide-model baler also features a multi-purpose door that can serve as a bale separator, bale release, or bale clamp. As with our other Galaxy 2R wide-model balers, the Apollo comes with components such as a high-efficiency power unit, adjustable shear beam, replaceable and reversible shear blades, and main ram and ejector-ram laser positioning.

.

Have Questions About Apollo TWO-RAM Recycling BALERS?

Contact your local Marathon Recycling Compaction team today to request a complimentary site survey.

5 Yr. Structure | 1 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Transfer Compaction & Recycling Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. The existing Marathon Recycling Solutions Warranty has also been updated to include Transfer Compactors. The Transfer Compactor and Recycling Solutions Warranty include 5-years structural warranty, 1-years part warranty, and 1-year labor warranty.Key Features:

- Automatic Accent model 470 wire tier standard

- Adjustable gib bars (hold-downs) from outside the machine

- Infrared actuators (two sets)

- Regenerative hydraulic circuit

- Ram shear blade is replaceable and reversible

- Body shear blade is serrated and replaceable

- Free-standing operator center with PLC controls and 10″ color touchscreen interface

Apollo Two-Ram Baler standard Features

Automatic Accent model 470 wire tier is standard equipment on all Marathon Galaxy two-ram balers

The Apollo Two-Ram Baler features adjustable gib bars (hold-downs), which are accessible from outside of the baler machine

Marathon Apollo Two-Ram Recycling Balers feature two sets of Infrared actuators

Marathon Apollo Two-Ram recycling balers feature a regenerative hydraulic circuit

The Apollo Two-Ram Baler’s Ram shear blade is replaceable and reversible for ease of maintenance and long life

The Apollo Two-Ram recycling baler’s body shear blade is serrated and replaceable for enhanced performance and ease of maintenance

The Apollo Two-Ram recycling baler features a free-standing operator center with PLC controls and large 10″ color touchscreen interface

Configurable For Your Specific Application

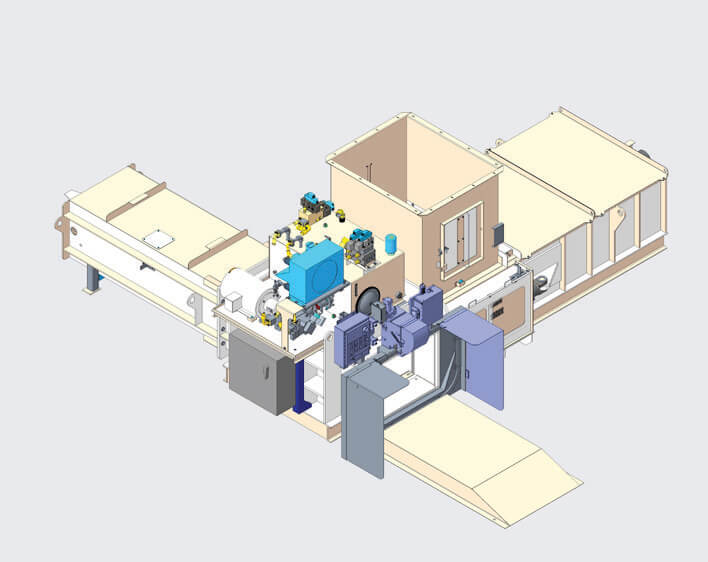

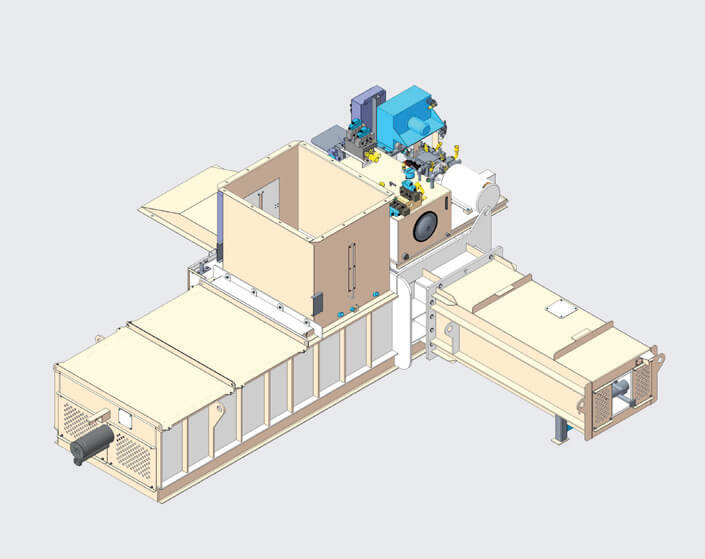

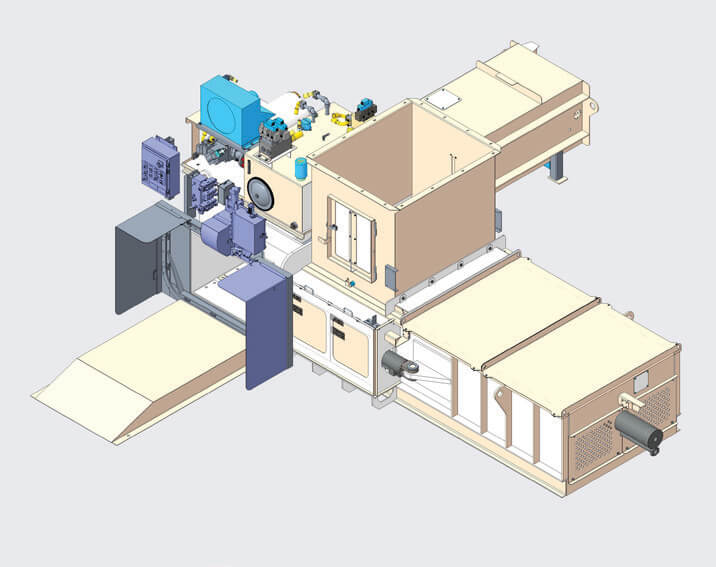

FRONT VIEW

REAR VIEW

SIDE VIEW

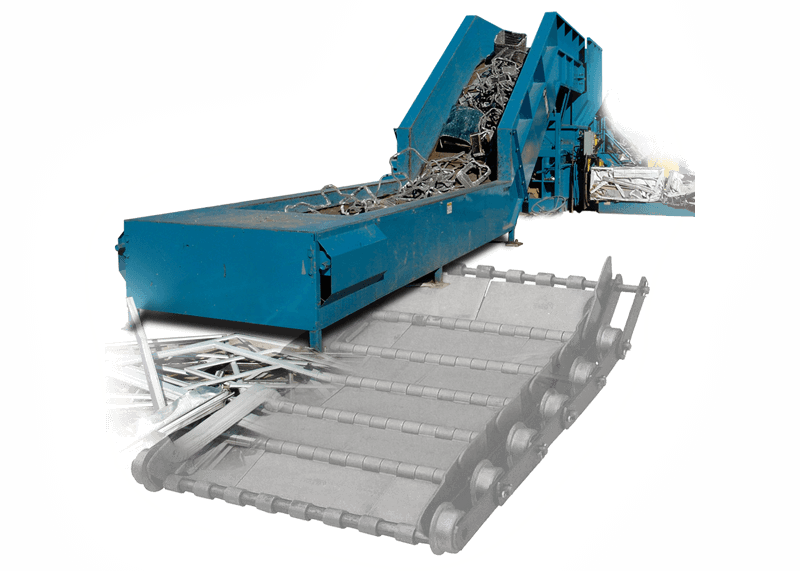

EZ-TRAX Conveyors

Marathon Recycling Solutions offers custom engineered conveying systems to handle a wide variety of bulk material and scrap-handling applications. These range from light-duty slider beds to heavy-duty steel belt conveyors and complete turnkey MRF systems.

Factory Start-ups

Marathon provides on-site set-up and comprehensive baler operation training for your personnel.

Apollo Two-Ram Baler OPTIONAL Features

Add a High-definition camera and monitor to the Apollo Two-Ram recycling baler to easily detect non-compliant material and contamination

The Apollo Two-Ram recycling balers has optional easy and convenient to use controls for ancillary conveyor in-feed system, the VFD (variable frequency drive) provides for variable speed control of the conveyor belt

The optional Apollo Two-Ram baler oil heater allows for continuous use of the baler, even in extreme temperature conditions

Enhances the durability and life of the Apollo Two-Ram recycling baler with tongue and groover floor, while providing a replaceable wear surface for easier maintenance.