EZ-Trax Recycling Conveyor Systems

The preferred choice for Recycling Solutions

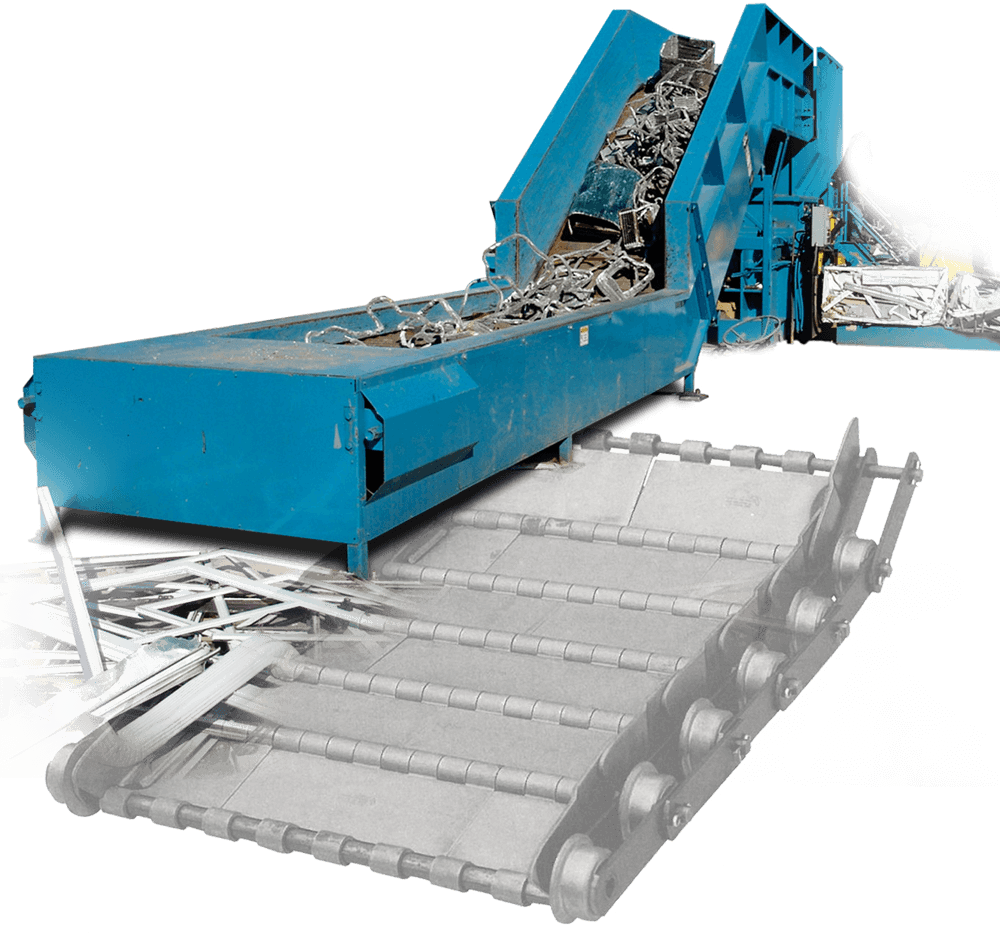

Marathon® offers custom-engineered recycling conveying systems to handle a wide variety of bulky recycled materials and scrap-handling applications. The EZ-Trax® recycling conveyor systems range from light-duty sliderbeds to heavy-duty steel belt conveyors and complete turn-key Material Recovery Facility (MRF) systems.

Have Questions About EZ-Trax Recycling Conveyor Systems?

Contact your local Marathon Recycling Compaction team today to request a complimentary site survey.

5 Yr. Structure | 1 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Transfer Compaction & Recycling Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. The existing Marathon Recycling Solutions Warranty has also been updated to include Transfer Compactors. The Transfer Compactor and Recycling Solutions Warranty include 5-years structural warranty, 1-years part warranty, and 1-year labor warranty.ez-trax conveyor types and applications

Heavy-duty conveyors that feature a chain-drive system incorporated with a rubber belt for medium to high-volume applications.

Friction-driven conveyors with a belt supporting bed for low to medium-volume bulk material handling applications. These conveyors can be used for baler and compactor feeds, sorting lines, and components of a MRF system.

Ideal for medium- to heavy-duty applications such as precrusher or compactor feeds, paper, solid waste, large-scrap baler feeds, and mixed waste lines.

For the most demanding, high-impact, heavy-duty operations such as transfer stations, scrap, MSW and C&D lines, mixed waste lines, and abrasive materials.

Designed to convey material at a higher speed. The rubber belt rides on angled rollers or idlers that form a trough. Used for light to medium-duty balers, compactors, and shredder feeds.

Infinitely customizable Recycling Conveyor Systems

Customized For Your MRF

EZ-TRAX Conveyors fit many applications, such as this MRF in Lakeville, MA. It features dozens of sliderbed conveyors, sorting lines, sorting bins, platforms, and baler feed combination steel-belt conveyors.

Conveyors For All MRF Sizes

This smaller MRF, located in Bedford County, VA, has a sliderbed sorting line conveyor fed by a combination chain-belt conveyor.

Ideal for baler/compactor feed

EZ-TRAX sliderbed and steel-belt conveyors are ideal add-ons for baler and compactor-feed applications. They add efficiency to optimize productivity and throughput capacity. This below-ground sliderbed is feeding a Gemini® 3560 manual-tie, horizontal baler.