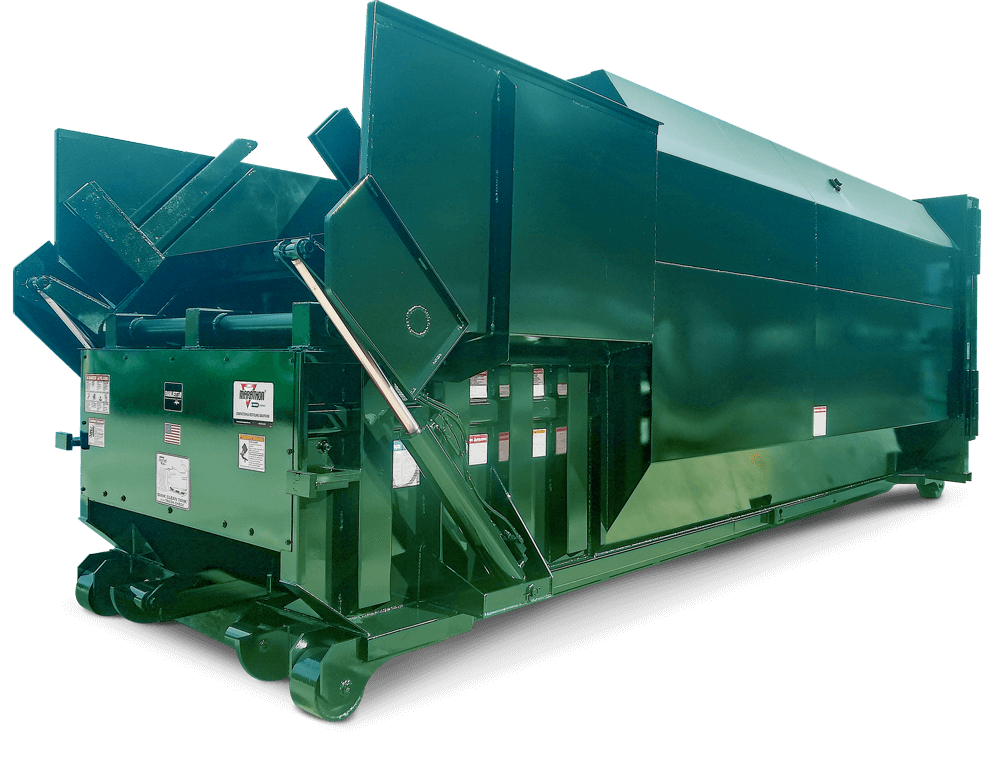

RJ-250WD Self-Contained Compactor With Built-in integral Cart Dumper

The Marathon® RamJet® RJ-250WD Self-Contained Trash Compactor with built-in cart dumper / lifter is the perfect compactor for weekly volumes of more than 100 cubic yards of wet or general waste materials. All models have a packer head with integral cart dumping/lifting mechanism permanently attached to the compactor container.

RamJet RJ-250WD units are state-of-the-art in roll-off self-contained compactors, featuring large feed openings and expanded container storage capacity. They are designed to optimize safety for workers, store and transport waste, prevent contamination of public areas in accordance with public health department requirements, improve working conditions for employees, and reduce hauling costs.

The RJ-250WD trash compactor with built-in cart dumper / lifter can be customized with a variety of loading arrangements and options to suit your specific needs.

Have Questions About The RJ-250WD Trash Compactor?

Contact your local Marathon Compaction team today to request a complimentary site survey.

3 Yr. Structure | 2 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Compaction Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. Our existing Signature Series® Warranty, Compactor Warranty, and Auger Warranties have been combined into a new Compaction Solutions Warranty. The Compaction Solutions Warranty includes 3-year structural warranty, 2-year part warranty, and 1-year labor warranty.The RJ-250WD Cart Dumper System

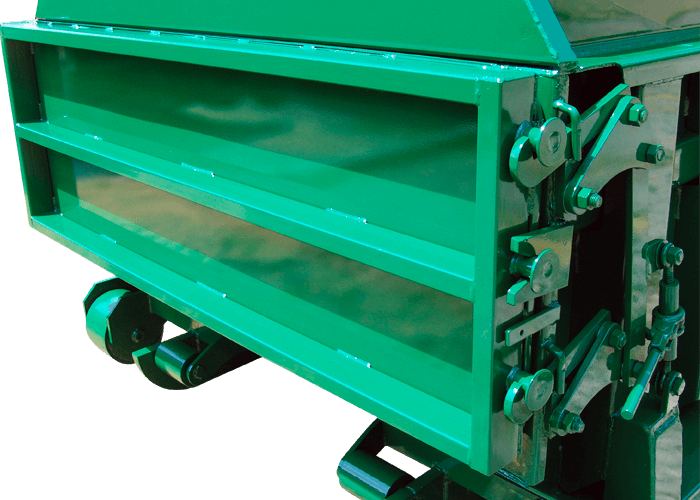

Equipped with an integral ground-level cart dumper system, this RJ-250WD is ideal for sprawling apartment complexes, shopping centers, parks, resorts, and other applications where a centralized disposal system is needed. “Trainable” carts can be located in convenient locations throughout the facility and periodically towed to the compactor. The compactor ram automatically retracts when the cart is being lifted so that the full capacity of the charge box is available for trash being dumped. Forks remain in “full dump” position for transit to and from the disposal site.

RJ-250WD Compactor Features & Benefits

- Great for waste with high liquid content

- Qwik Clean® Tank

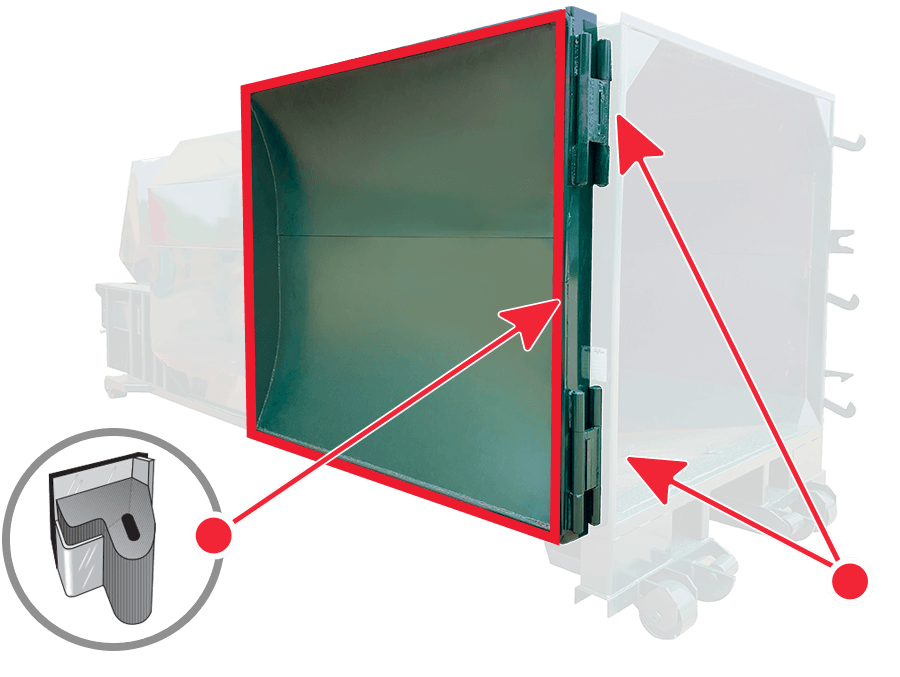

- Full door seal with P-Seal

- CYCON Life-Xtender®

- Cyclic Control System

- Customizable for your application

- Exclusive 41″ x 58″ feed opening to handle even large, bulky items

- Continuous feeding capability — even while the compactor is operating

- Easy loading from either ground or dock level

- Up to 24 tons of crushing force to reduce refuse to a fraction of its former size, saving valuable space

- Fire hose connection provided on each unit

- Factory testing to ensure leak-proof construction

RJ-250WD Self-Contained Compactor KEY Features

Factory testing to ensure leak-proof construction

Easy loading from either ground or dock level.

41″ x 58″ feed opening to handle even large, bulky items

Continuous feeding capability — even while the compactor is operating

Up to 24 tons of crushing force to reduce refuse to a fraction of its former size, saving valuable space and reducing your number of hauls

The Qwik Clean Tank feature, standard on all RJ-250WD compactors, funnels any liquid seepage which occurs during compaction into an enclosed area underneath the charge box floor. The liquid is automatically discharged at the disposal site, in effect flushing the container and the area behind the ram. The 12″ high, up to 750-gallon capacity sump area is designed to provide easier hook access for roll-off drivers.

Separate from the compactor/container, the Marathon Remote Power Pack remains free of damage caused during hauling to and from disposal sites and free of problems caused by landfill dust. Two simple-to-use, hydraulic quick disconnect fittings couple the power unit to the packing head. All Marathon Remote Power Packs are built in-house to our quality standards and each unit must pass a series of stringent tests before it can be shipped with the selected compactor.

CYCON LIFE-XTENDER CYCLIC CONTROL SYSTEM

Standard on all RJ-250WD Compactors

- Reliable, solid-state circuitry eliminates all pressure and limit switches

- The Cycon Life-Xtender no shock cycle control extends cylinder and hose wear life

- Automatic “container full assurance system” — the ram dwells against the load at full pressure, resulting in better compaction

- Smoother running, quieter operation

- Advanced hydraulic design enables the system to operate at minimum pressure levels until the need for more pressure is automatically sensed

- More accurate Advanced Warning or Container Full options

- Dramatically improved cold-weather performance

P-Seal Watertight Closure

The P-shaped Door Seal is specially designed for portable compaction containers to provide a superior watertight closure. The mounting is engineered for quick and easy installation when replacement is necessary, requiring no field fitting, cutting, or welding.

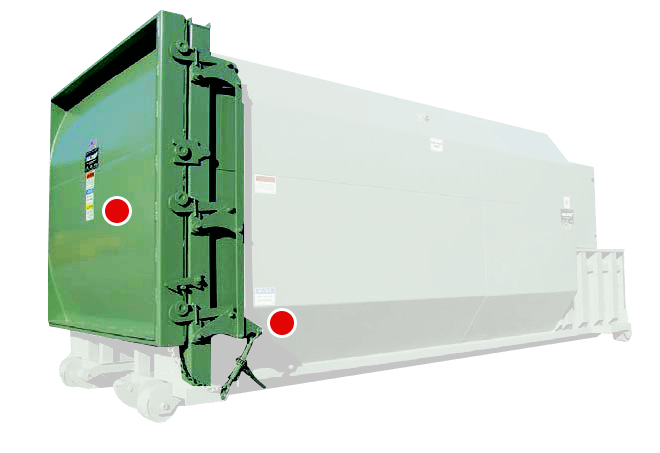

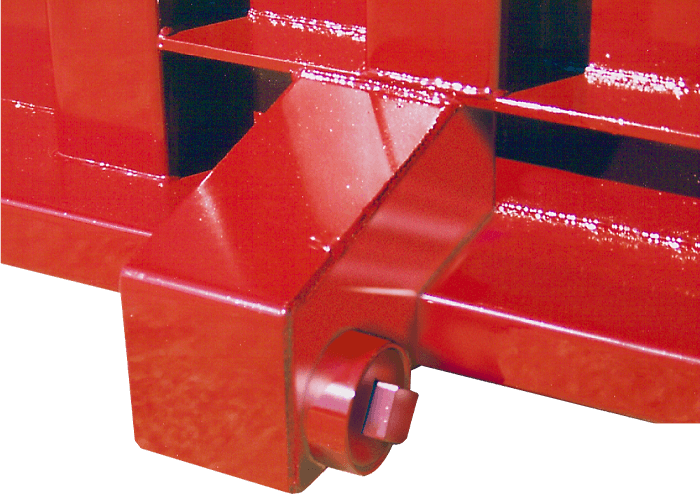

Double-Hinge with Bronze Bushing

Every RJ-250WD is tested for watertightness before leaving the factory. Liquid retention is ensured by the incredible Double-Hinge. It creates uniform seal compression while eliminating the seal “scrubbing” and damage so often encountered with competitive designs. The Double-Hinge also saves expensive driver and truck time because only one easy-to-operate ratchet is required to make it work.

BUBBLE GATE

The innovative “Bubble Gate” adds a full cubic yard to container capacity. Superior compaction ratios result from its special curved shape. These two unique benefits reduce costs of disposal.

Auto relatch

The ultimate in latch systems, the Marathon “Auto Relatch” eliminates the need to hold the door while operating the latch ratchet. This design enables the operator to use both hands on the ratchet.

Ram Guide System

The packing ram is supported by specially formulated cast-iron shoes which ride on replaceable wear strips. This exclusive design protects the charge-box floor from the full force of the packing ram, extending its life and dramatically reducing compaction-robbing friction.

RJ-250WD Self-Contained Compactor Options

Optional Doghouse

An optional doghouse offers a totally enclosed charge box with heavy-duty latches.

Qwik Clean Door

The Qwik Clean door on the packer end makes cleaning out behind the ram in cylinder area a snap. The door has miniature hinges, a door seal, and a ratchet binder

StreamLine Option

The StreamLine® option enables excess liquid to be drained from the container, reducing net payload weight and significantly reducing hauling costs. Liquid is routed to four interconnected 4″ drain outlets located at each corner of the StreamLine unit. Connection can be made to a hose, piping, or a pump.

Our RamJet RJ-250WD units are state-of-the-art in roll-off self-contained compactors, featuring large feed openings and expanded container storage capacity. They are designed to optimize safety for workers, store and transport your waste, prevent contamination of public areas in accordance with public health department requirements, improve working conditions for your employees, and reduce disposal costs.

- Easy rear access for cleaning

- Improved cylinder/pin access

- Great for waste with high liquid content

- Improved compactor life

- Newly designed raised packer head cylinders

- Interchangeable with most existing RJ-250SC applications

AVAILABLE WITH BAYNE THINLINE CART LIFTER

Equipped with an integral cart lifter, the RJ-250WD offers an economical and safety-conscious solution for a wide variety of waste material handling applications.

Bayne® Thinline® cart lifters work with standard two-bar roll-out carts and can lift up to 750 lbs. Lifters have a durable, powder-coated finish that can stand up to the elements.

PERFECT FOR TIPPER-SYSTEM APPLICATIONS

The RJ-250WD is the perfect choice for applications requiring a tipper system. These tippers can extend the benefits of compaction to all areas of operation while keeping equipment investments to a minimum. Carts or containers can be located at individual waste generation sites within the operation, and then emptied into the compactor with the cart-tipper option.