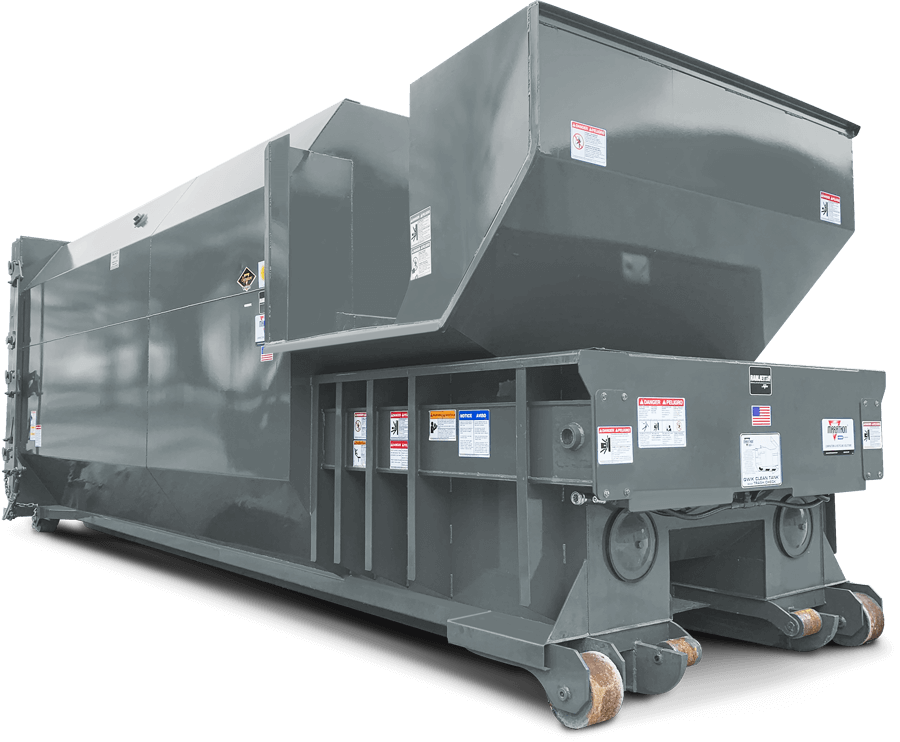

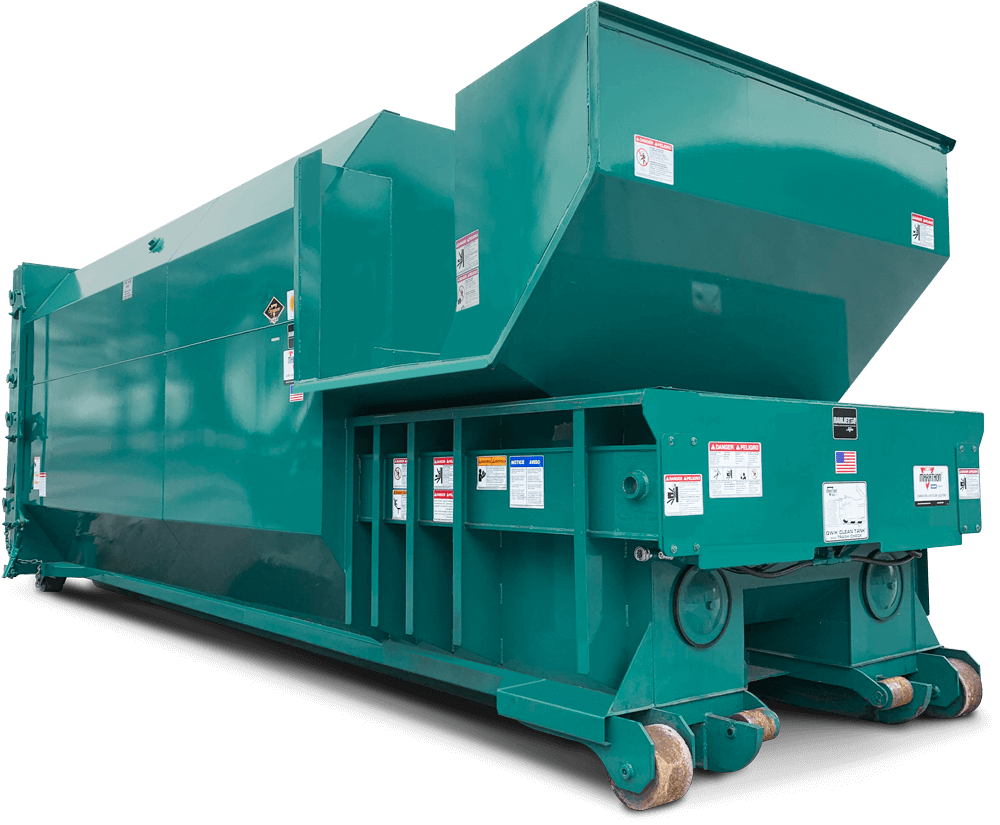

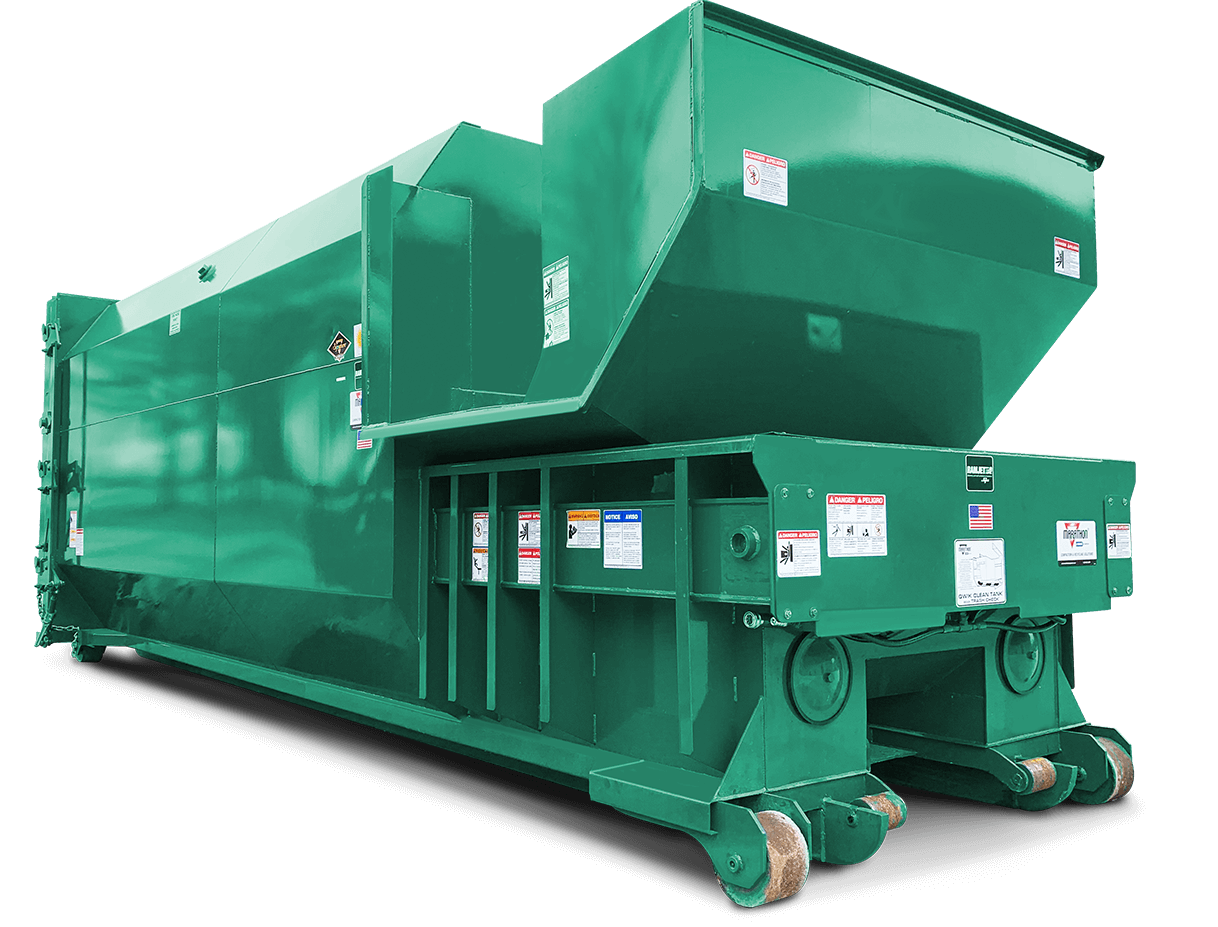

SC SELF-CONTAINED Roll-Off TRASH COMPACTORs

Marathon® RamJet® SC2™ units are state-of-the-art in roll-off self-contained trash compactors, featuring large feed openings and expanded container storage capacity. They are designed to optimize safety for workers, store and transport your waste, prevent contamination of public areas in accordance with public health department requirements, improve working conditions for your employees, and reduce disposal costs.

Marathon SC2 trash compactors can be customized with a variety of loading arrangements and compactor options to suit your specific needs.

Have Questions About The SC2 Trash Compactor?

Contact your local Marathon Compaction team today to request a complimentary site survey.

7 Yr. Structure | 5 Yr. Parts | 3 Yr. Labor

Introducing The Marathon SC2 Warranty

As leaders in the compaction and recycling market, we know when we’ve developed a game-changer. We’re so sure that the innovations of the new SC2 will deliver the most reliable and easy-to-maintain compactors on the market, that we’ve put our money where our mouth is. Introducing the 7-5-3 Comprehensive Warranty Program on the new Marathon SC2 compactor. With the SC2, product workmanship is covered for seven years, parts are covered for five years, and labor is covered for three.SC2 Stationary Compactor Features & Benefits

- Great for waste with high liquid content

- New packer head design raises cylinders to a higher parallel position, away from harmful, abrasive waste, and liquid

- Heavy-Duty Wiper and Drag Plate, plus standard 1/2″ Packer Floor improvements greatly increase the life of the compactor

- New packer head design has 50% fewer internal hydraulic hoses, which reduces maintenance and repair costs

- Deck heights of 44″ and 48″ allow for easy loading from either ground or dock level

- Clean-outs behind the ram and rear cylinder pin access are both easily accessible from outside the compactor body at ground level

- 40 1/2″ x 56 1/2″ feed opening to handle large, bulky items

- Continuous feeding capability — even while the compactor is operating

- Adaptable to special loading systems, such as large-capacity hoppers, security chutes, or total enclosures

- Odor and pest control from the Marathon Ozone Odor Control options

- Up to 25 tons of crushing force to reduce refuse to a fraction of its former size, saving valuable space and reducing your number of hauls

SC2 Self-Contained Compactor Standard Features

New packer head design raises cylinders to a higher parallel position, away from harmful, abrasive waste, and liquid. Additionally, the head design has 50% fewer internal hydraulic hoses, which reduces maintenance and repair costs.

Heavy-Duty Wiper and Drag Plate plus standard 1/2″ Packer Floor improvements greatly increase the life of the compactor.

Deck heights of 44″ and 48″ allow for easy loading from either ground or dock level.

Clean-outs behind the ram and rear cylinder pin access are both easily accessible from outside the compactor body at ground level.

40 1 /2″ x 56 1 /2″ feed opening to handle large, bulky items.

Continuous feeding capability — even while the compactor is operating

Adaptable to special loading systems, such as large-capacity hoppers, security chutes, or total enclosures.

Odor and pest control from the Marathon Ozone Odor Control options

Up to 25 tons of crushing force to reduce refuse to a fraction of its former size, saving valuable space and reducing your number of hauls

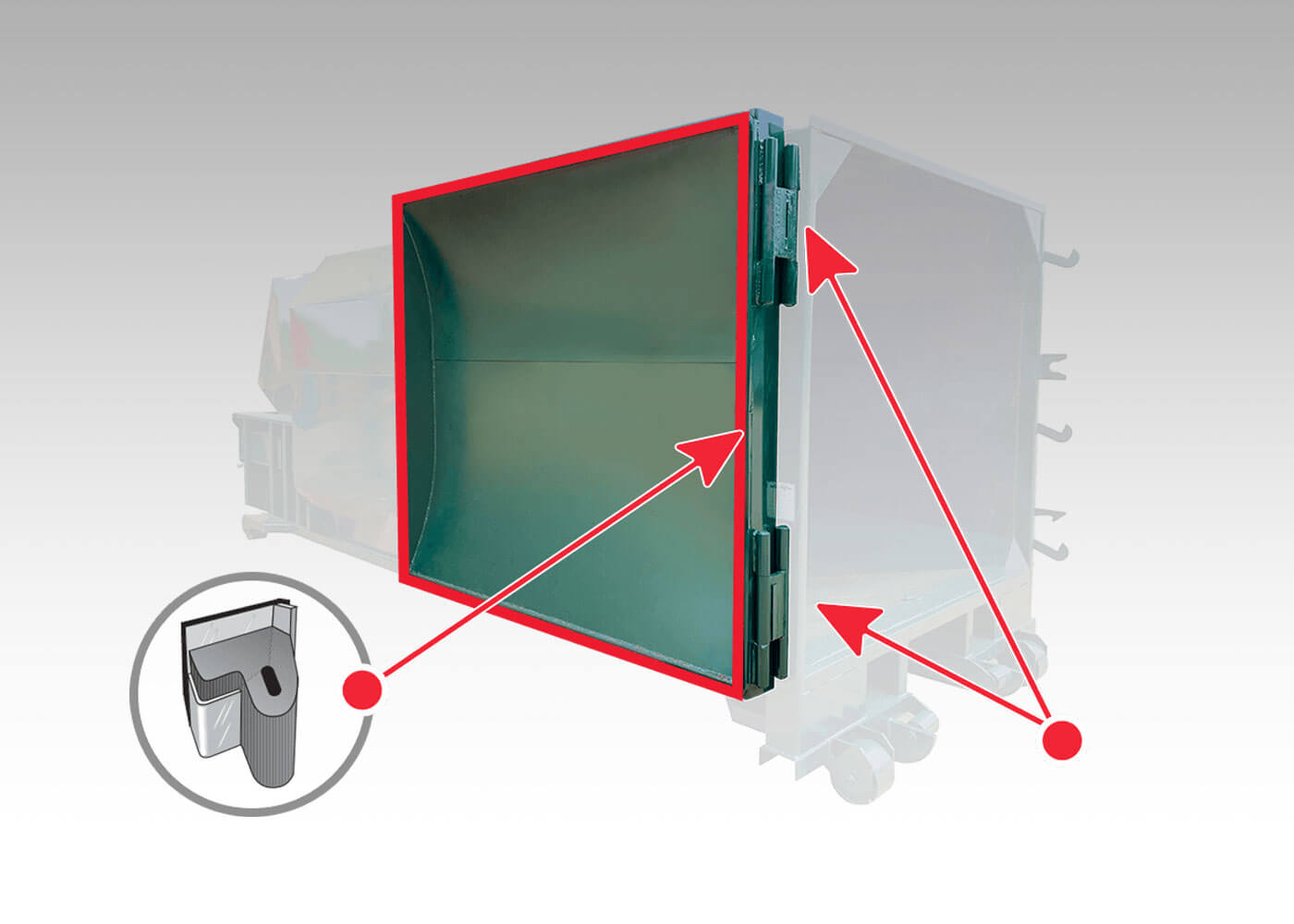

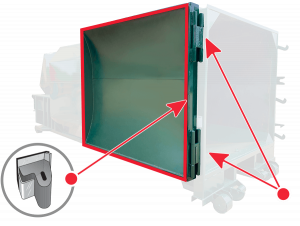

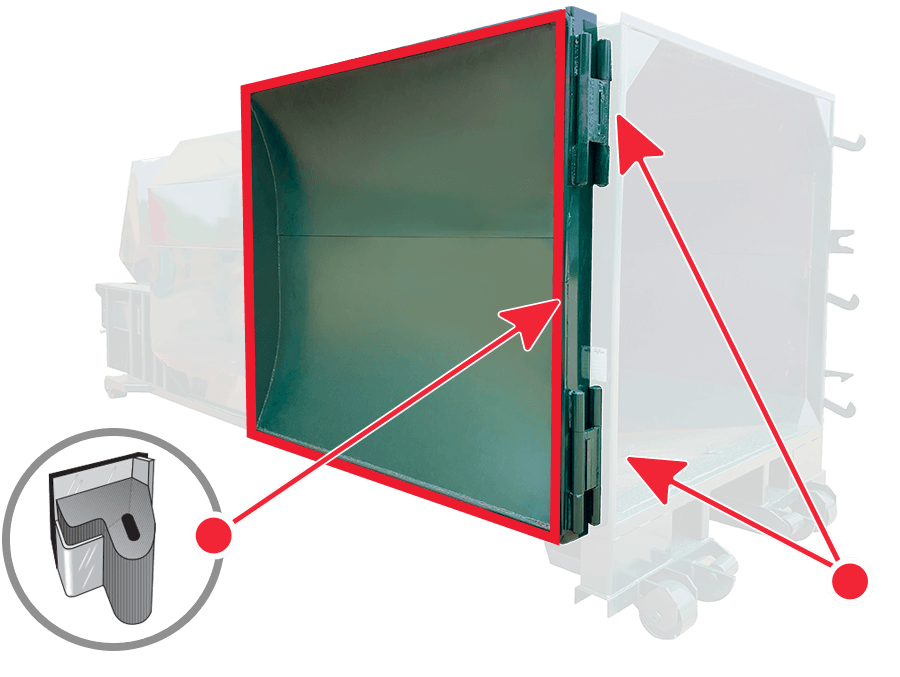

The P-shaped Door Seal is specially designed for portable compaction containers to provide a superior watertight closure. The mounting is engineered for quick and easy installation when replacement is necessary, requiring no field fitting, cutting, or welding.

Every unit is tested for watertightness before leaving the factory. Liquid retention is ensured by the incredible double-hinge. It creates uniform seal compression while eliminating the seal “scrubbing” and damage so often encountered with competitive designs. The double-hinge also saves expensive driver and truck time because only one easy-to-operate ratchet is required to make it work.

The ultimate in latch systems, the “Auto Relatch” eliminates the need to hold the door while operating the latch ratchet. This design enables the operator to use both hands on the ratchet, and prevents the door from swinging out inadvertently.

The innovative “Bubble Gate” adds a full cubic yard to container capacity. Superior compaction ratios result from its special curved shape. These two unique benefits reduce the costs of hauling.

Separate from the compactor/container, the Marathon Remote Power Pack remains free of damage caused during hauling to and from disposal sites and free of problems caused by landfill dust. Two simple-to-use, hydraulic quick-disconnect fittings couple the power unit to the packing head.

All Marathon Remote Power Packs are built in-house to our quality standards and each unit must pass a series of stringent tests before it can be shipped with the selected compactor.

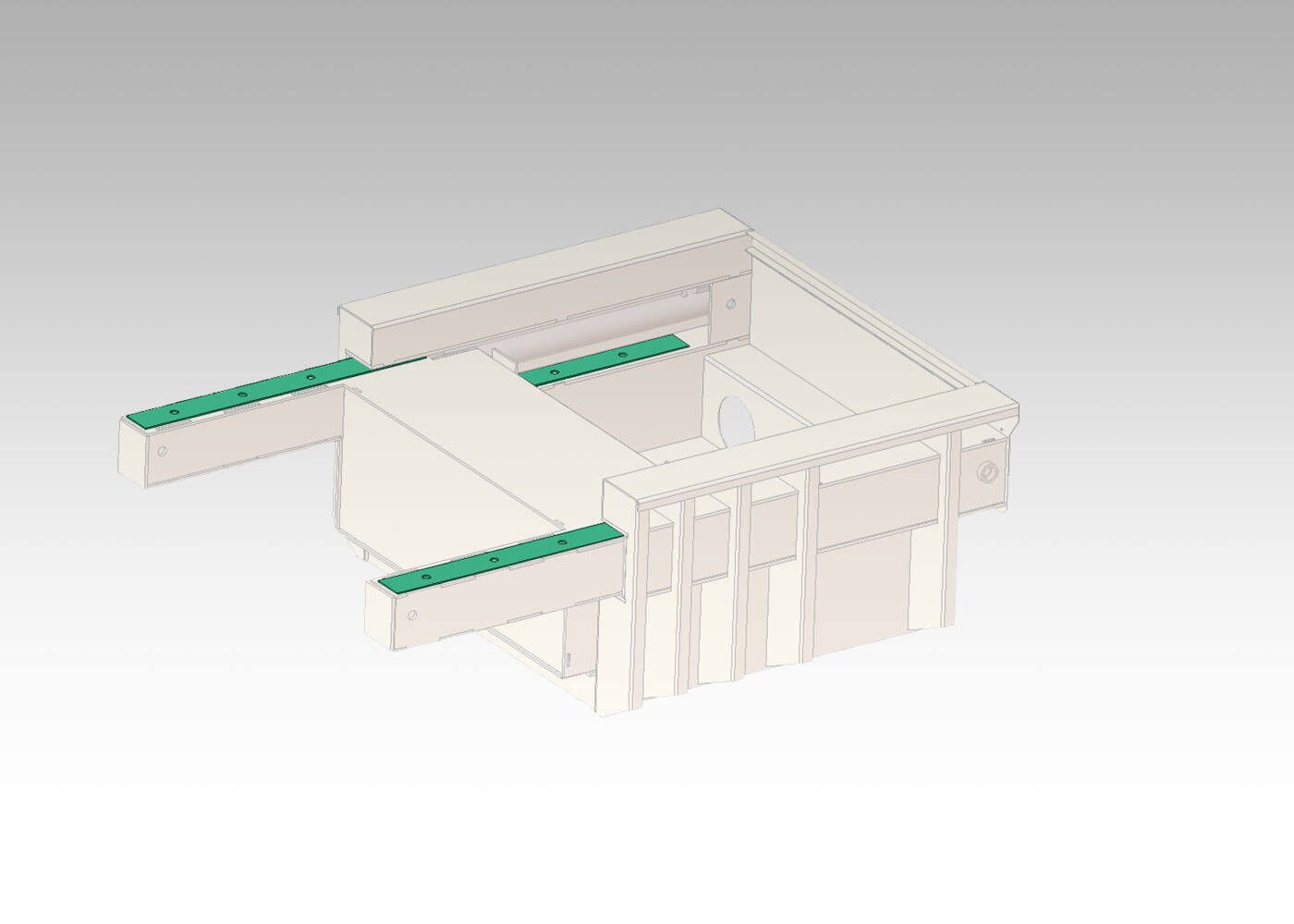

Open and uncluttered compartment combined with a flat floor and quick removal cleaning ports will save time and facilitate more frequent cleaning, extending the life of internal components. Newly designed cylinders also allow for easy removal at the rear of the compactor.

The redesigned non-rotating cylinders are raised 18″ off the floor to move them further away from any accumulated liquid and debris. Fixed cylinder body, plumbing, and pins are housed in the side pockets, eliminating the need for movement or rotation. This redesign also allows for fewer hoses, which reduces maintenance and repair costs.

P-Seal Watertight Closure

The P-shaped Door Seal is specially designed for portable compaction containers to provide a superior watertight closure. The mounting is engineered for quick and easy installation when replacement is necessary, requiring no field fitting, cutting, or welding.

Double-Hinge with Bronze Bushing

Every SC2 is tested for watertightness before leaving the factory. Liquid retention is ensured by the incredible double-hinge. It creates uniform seal compression while eliminating the seal “scrubbing” and damage so often encountered with competitive designs. The double-hinge also saves expensive driver and truck time because only one easy-to-operate ratchet is required to make it work.

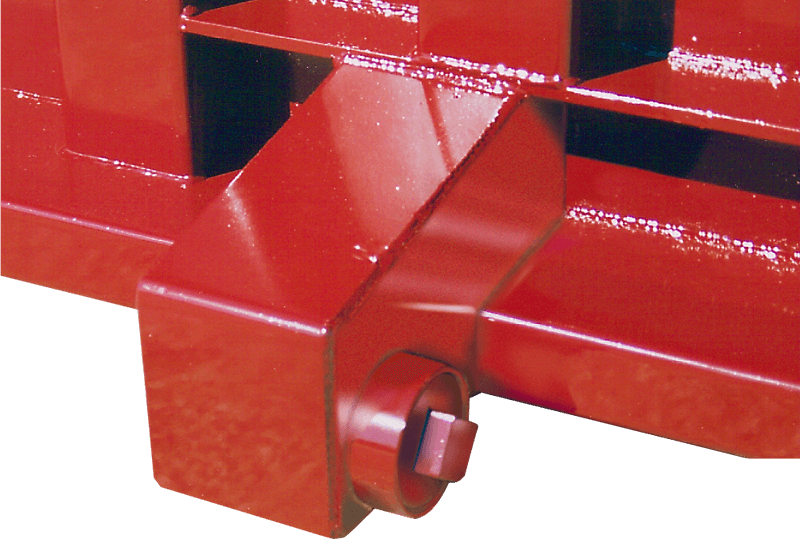

Auto Relatch

The ultimate in latch systems, the “Auto Relatch” eliminates the need to hold the door while operating the latch ratchet. This design enables the operator to use both hands on the ratchet, and prevents the door from swinging out inadvertently.

Bubble Gate

The innovative “Bubble Gate” adds a full cubic yard to container capacity. Superior compaction ratios result from its special curved shape. These two unique benefits reduce the costs of hauling.

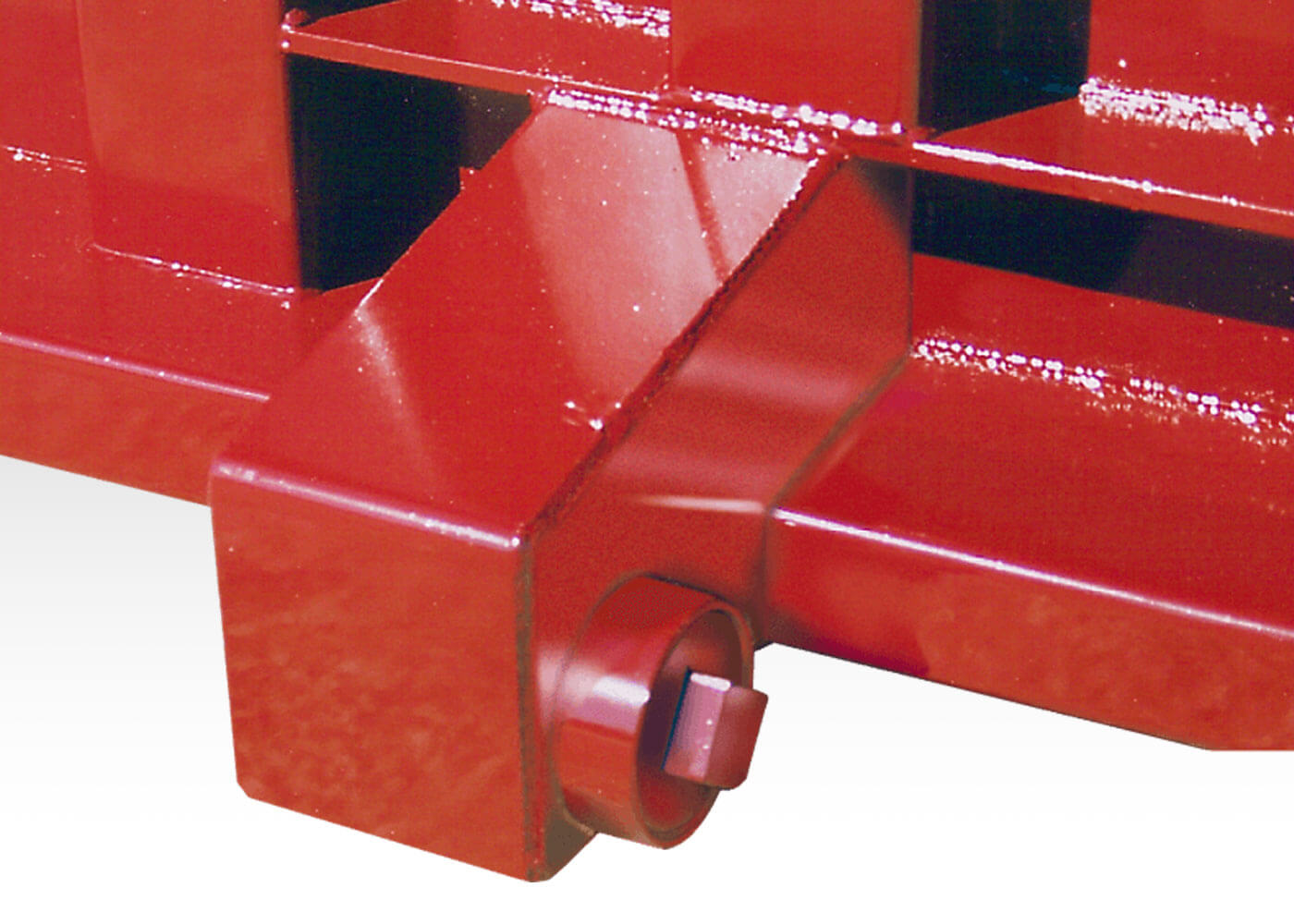

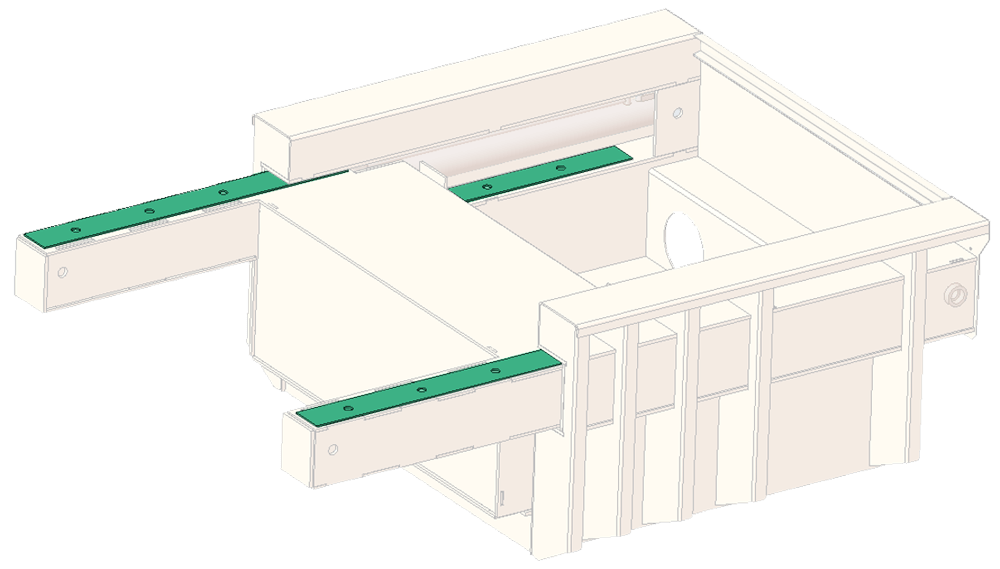

AR500 Guide Plates

The packing ram is supported by an improved abrasion-resistant guide system. This exclusive design protects the charge-box floor from the full force of the packing ram, extending its life and dramatically reducing compaction-robbing friction.

CYCON LIFE-XTENDER CYCLIC CONTROL SYSTEM

Standard on all SC2 Compactors

- Reliable PLC controls eliminates the need for limit switches

- The Cycon Life-Xtender® no shock cycle control extends cylinder and hose wear life

- Automatic “container full assurance system” — the ram dwells against the load at full pressure, resulting in better compaction

- Smoother running, quieter operation

- Advanced hydraulic design enables the system to operate at minimum pressure levels until the need for more pressure is automatically sensed

- More accurate Advanced Warning or Container Full options

- Dramatically improved coldweather performance

Rear Access for Quick Cleaning

Open and uncluttered compartment combined with a flat floor and quick removal cleaning ports will save time and facilitate more frequent cleaning, extending the life of internal components. Newly designed cylinders also allow for easy removal at the rear of the compactor.

Remote Power Pack

Separate from the compactor/container, the Marathon Remote Power Pack remains free of damage caused during hauling to and from disposal sites and free of problems caused by landfill dust. Two simple-to-use, hydraulic quick-disconnect fittings couple the power unit to the packing head.

All Marathon Remote Power Packs are built in-house to our quality standards and each unit must pass a series of stringent tests before it can be shipped with the selected compactor.

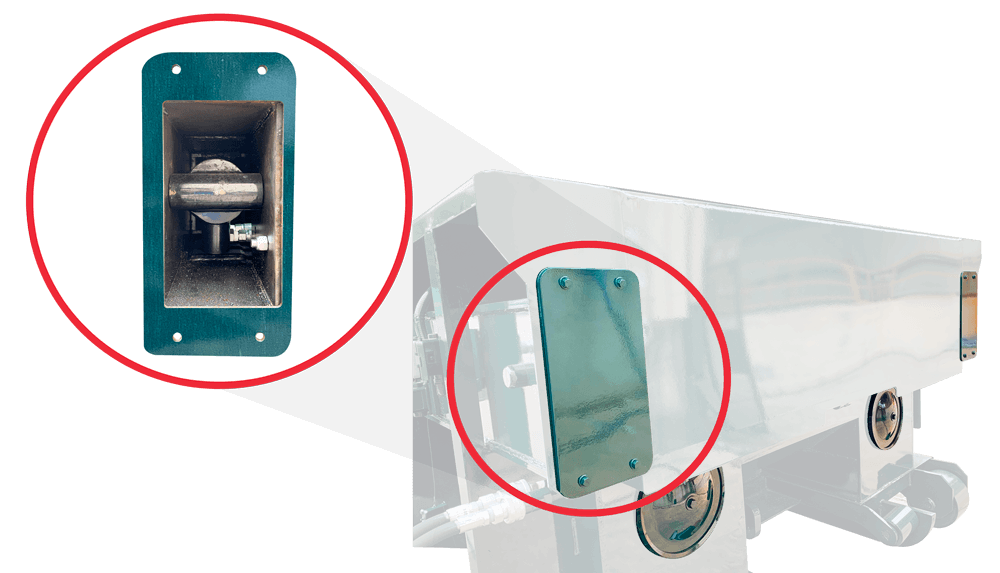

Improved Fixed Cylinder-Pin Mounting

The redesigned non-rotating cylinders are raised 18″ off the floor to move them further away from any accumulated liquid and debris. Fixed cylinder body, plumbing, and pins are housed in the side pockets, eliminating the need for movement or rotation. This redesign also allows for fewer hoses, which reduces maintenance and repair costs.

PERFECT FOR TIPPER-SYSTEM APPLICATIONS

The SC2 is the perfect choice for applications requiring a tipper system. These tippers can extend the benefits of compaction to all areas of operation while keeping equipment investments to a minimum. Carts or containers can be located at individual waste generation sites within the operation, and then emptied into the compactor with the cart-tipper option.

SC2 Self-Contained Compactor Options

Optional Doghouse

The optional doghouse offers a totally enclosed charge box with heavy-duty latches, making the machine lockable.

Streamline Option

The Streamline® option enables excess liquid to be drained from the container, reducing net-payload weight and significantly reducing hauling costs.

Connected asset solutions

Connected Collections® provides the ultimate series of solutions that ensure peace of mind, efficiency, and profitability to “back-of-store” operations.