Side-eject manual-tie horizontal Recycling Balers

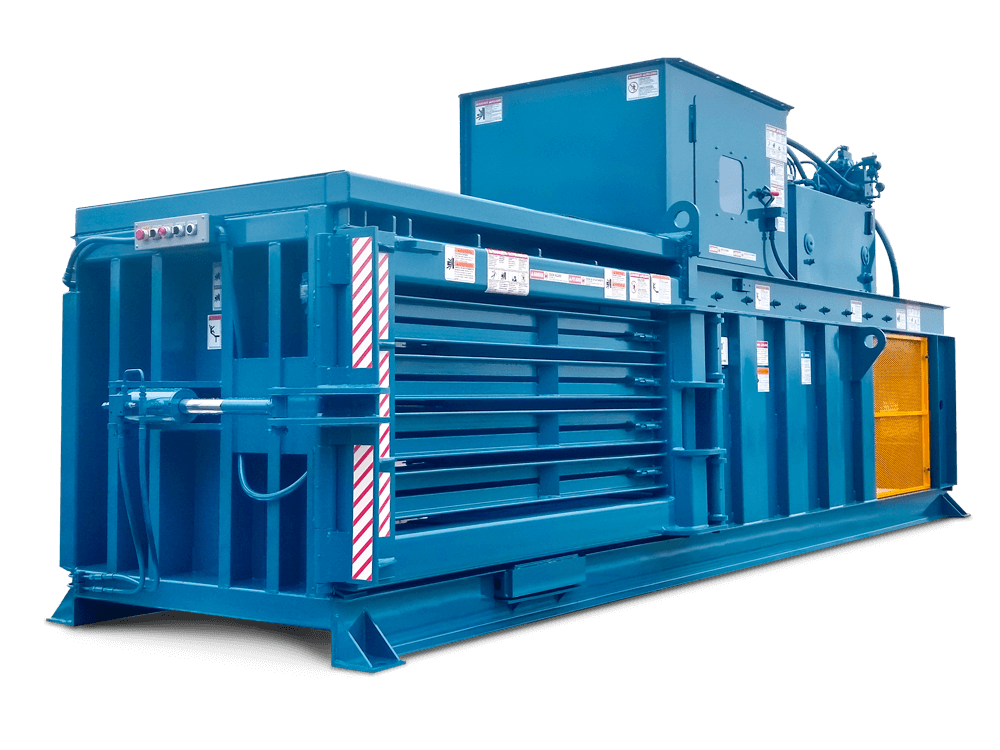

The Marathon® patented line of Side-Eject Horizontal Recycling Balers are uniquely engineered to maximize productivity. They include many features not found on conventional closed-end balers:

- Switch recyclables without contamination and maximize the value of your product

- Minimize spillage between bales and reduce the need to “double handle” materials

- Remove finished bales quickly and automatically to improve efficiency

- Front bale tie off saves valuable floor space and eliminates trips behind the baler

Have Questions About SIDE-EJECT MANUAL-TIE HORIZONTAL Recycling BALERS

Contact your local Marathon Recycling Compaction team today to request a complimentary site survey.

5 Yr. Structure | 1 Yr. Parts | 1 Yr. Labor

Introducing The Marathon Transfer Compaction & Recycling Solutions Warranty

Marathon Equipment is pleased to announce the release of our updated Warranty Coverage program. This warranty will take effect and be applicable on all products sold on or after June 1, 2021. Please note: this warranty plan is not retroactive to products sold prior to June 1, 2021. The existing Marathon Recycling Solutions Warranty has also been updated to include Transfer Compactors. The Transfer Compactor and Recycling Solutions Warranty include 5-years structural warranty, 1-years part warranty, and 1-year labor warranty.Side-Eject Horizontal Baler Features & Benefits

- Increased product value by eliminating contamination between bales as the operator changes materials being processed.

- Maximum and consistent bale weights with the Marathon Bale Made Indicator, which signals that the bale is finished. No time consuming “flag pole” or manual measuring device to compromise bale quality.

- The Marathon exclusive front bale tie-off system allows the operator to quickly direct tie wires around the bale from the front of the baler. This eliminates the need to go behind the baler and loosen hanging wires that drag as a bale is made.

- Dramatically reduces spillage commonly found with conventional balers. No need to “double handle” materials being processed.

- Remove each bale from the bale chamber quickly and easily with the patented Marathon Side-Eject feature and Bale Server Island. Unlike conventional balers that require an operator and forklift to free the bale from the end of the bale chamber, the Marathon Side-Eject design provides consistent and complete bale ejection every time.

Side-eject manual-tie

horizontal baler standard Features

Switch recyclables without contamination and maximize the value of your product

Minimize spillage between bales and reduce the need to “double handle” materials

Remove each bale from the bale chamber quickly and easily with the patented Marathon Side-Eject feature and Bale Server Island. Unlike conventional balers that require an operator and forklift to free the bale from the end of the bale chamber, the Marathon Side-Eject design provides consistent and complete bale ejection every time.

Front bale tie off saves valuable floor space and eliminates trips behind the baler

Maximum and consistent bale weights with the Marathon Bale Made Indicator, which signals that the bale is finished. No time consuming “flag pole” or manual measuring device to compromise bale quality.

The Marathon exclusive front bale tie-off system allows the operator to quickly direct tie wires around the bale from the front of the baler. This eliminates the need to go behind the baler and loosen hanging wires that drag as a bale is made.

The chute feed hopper with inspection door and interlock switch will accommodate optional pneumatic, gravity, or conveyor feeding systems.

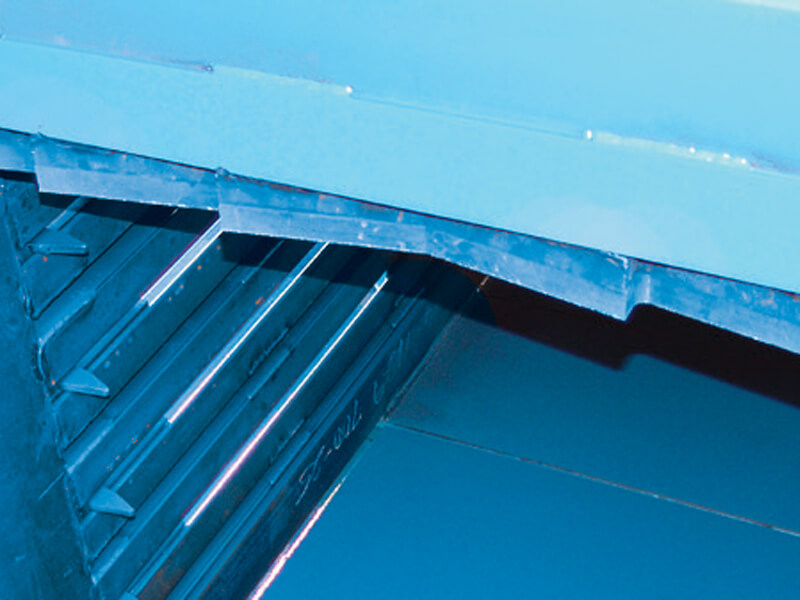

Spring-loaded container dogs are located on each side of the bale chamber to produce superior springback control of materials being processed.

Marathon Side-Eject Balers feature an hydraulic door latch, standard on all models.

Innovative Marathon Side-Eject Horizontal Baler Features

Chute-Feed Hopper

The chute feed hopper with inspection door and interlock switch will accommodate optional pneumatic, gravity, or conveyor feeding systems.

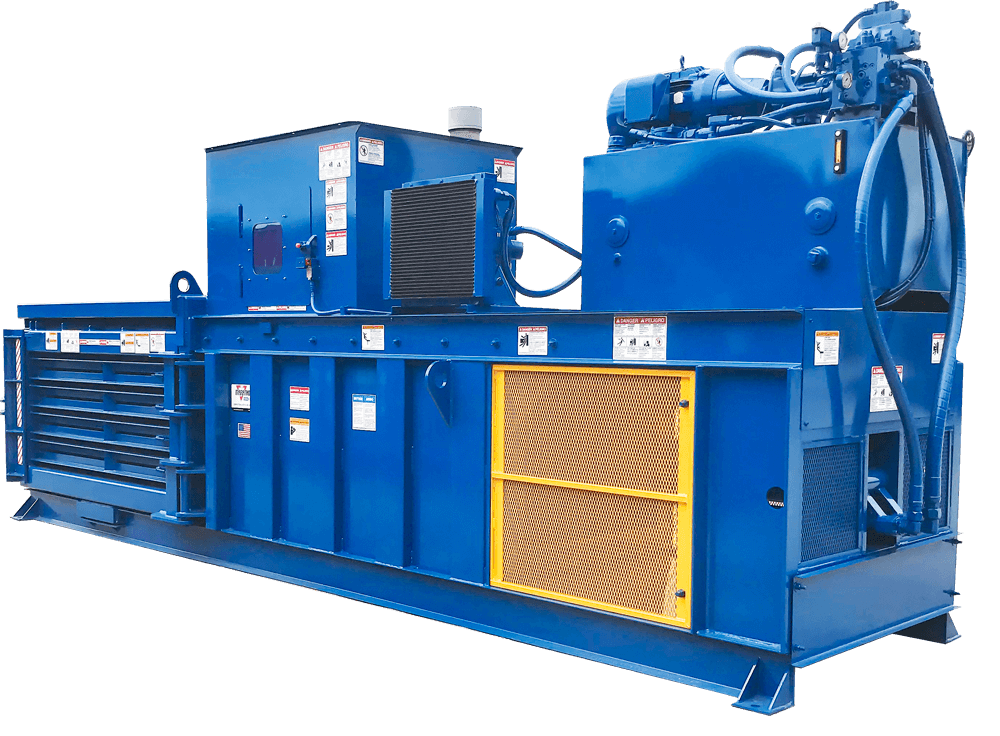

Advanced Power Pack

The advanced Marathon power pack is designed so that all of the valves are contained in a single manifold, which minimizes the number of hose connections and potential leak sources.

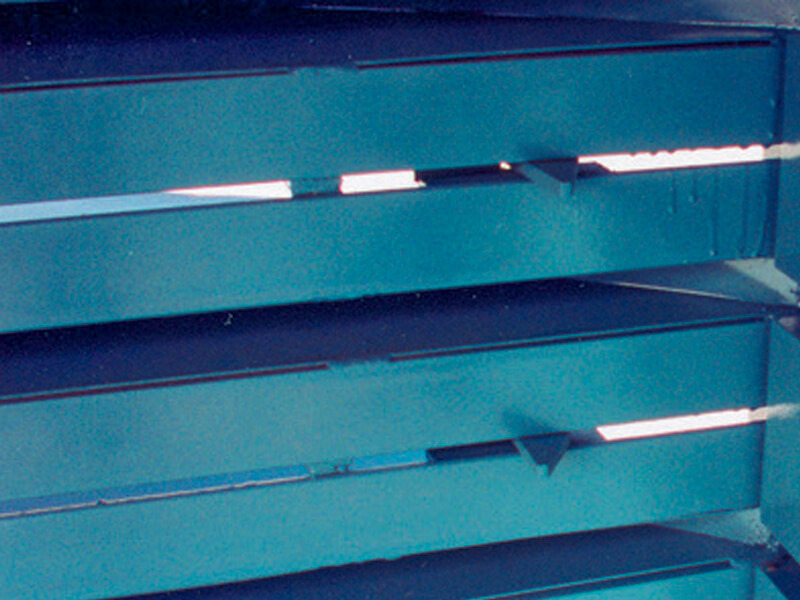

Spring-Loaded Container Dogs

Spring-loaded container dogs are located on each side of the bale chamber to produce superior spring back control of materials being processed.

Reliable Shear Blades

Bolt-on adjustable and replaceable shear blades cut material as a bale is made, and minimize problems associated with irregular bales sizes. This makes bales easier to tie and stack.

Hydraulic Door Latch

Marathon Side-Eject Balers feature an hydraulic door latch, standard on all models.

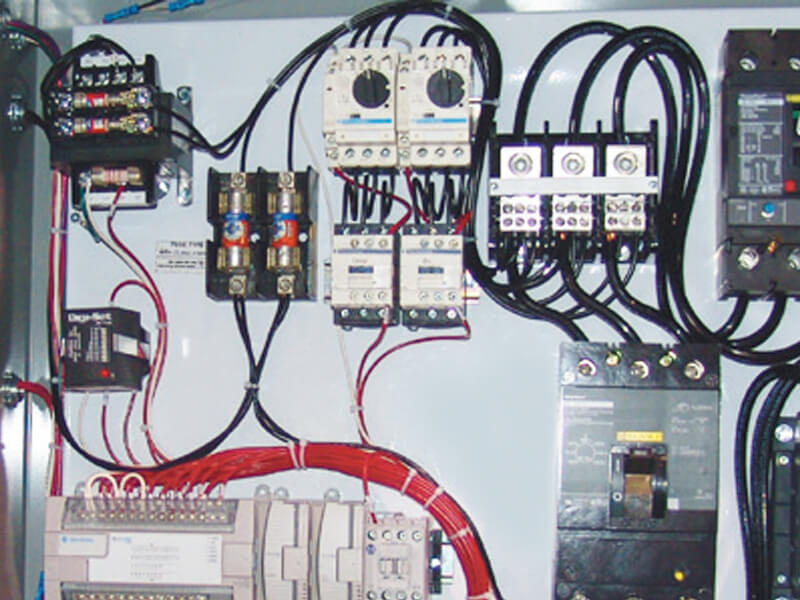

Programmable Controller

The programmable controller allows for customized programs to better meet customer needs. The controller eliminates the need for relays and timers that take up valuable panel space. All electrical components are UL and CUL listed.

Marathon Patented Automatic Side-Ejection Features Seamless Push Button Operation

Pressure is relieved from the bale in three directions to achieve positive and complete bale ejection from the chamber.

This advanced method of bale ejection begins by activating the “Home” button, which causes the platen to retract to a pre-set location relieving the end force on the bale. The operator then opens the chamber door, which relieves side force and automatically unlocks the hinged upper section of the chamber to relieve vertical force on the bale. With pressure on the bale effectively relieved from all directions, an hydraulic-powered Server Island, located on the floor of the bale chamber, quickly and completely pushes the bale out of the chamber. The Server Island functions as a pallet, eliminating costly construction of permanent guide islands. After the bale is removed with a forklift or pallet jack, the Server Island is retracted–saving valuable space.

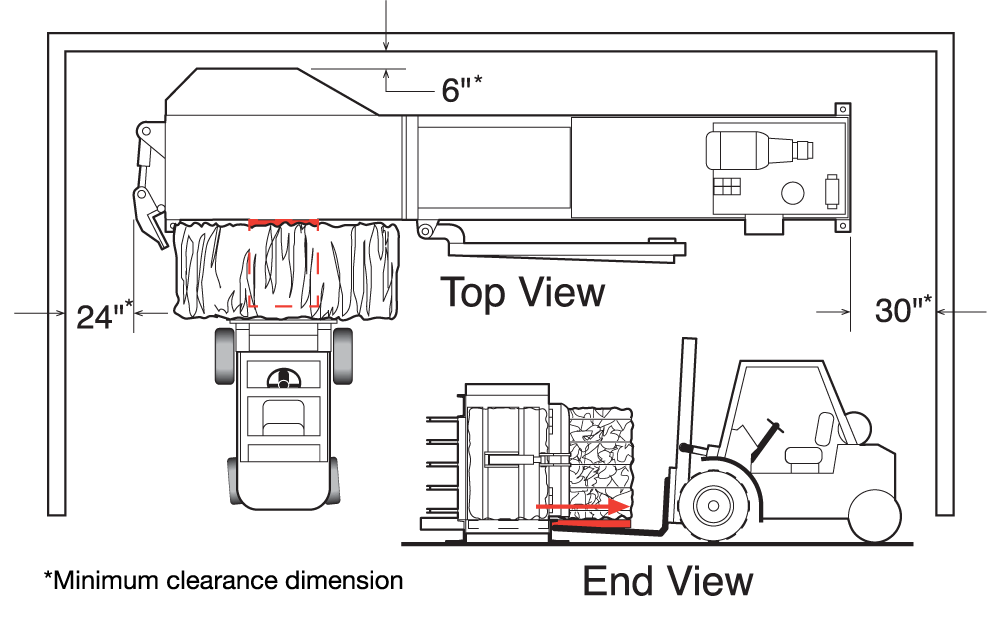

Space-saving Design – Install a Marathon Side-Eject Baler close to a wall or in a tight space. Minimal floor space is needed for operation due to the unique front baler tie-off feature and side-eject design.